In a hydraulic drive system, precise control of flow rate is a core element ensuring stable operation, and the relationship between pressure difference across a hydraulic resistance and flow rate represents a fundamental principle of hydraulic technology. The general expression describing this relationship is:

qv = KAΔpm

(Equation 1-10)

Each parameter in this equation embodies profound implications for fluid motion characteristics, and variations in the exponent m particularly reveal essential differences in flow characteristics under different flow channel structures. Understanding this relationship is crucial for optimizing performance in any hydraulic drive system.

Coefficient K

Coefficient K is a comprehensive parameter reflecting the inherent characteristics of the flow channel and the physical properties of the liquid. Its value primarily depends on the geometric shape of the flow passage, making it a critical factor in any hydraulic drive system design.

For circular pipes, the K value is proportional to the fourth power of the pipe diameter (according to Poiseuille's law). For irregular cross-sectional channels (such as rectangular or triangular), shape correction factors must be introduced, and generally, the K value decreases with an increase in cross-sectional angles.

The dynamic viscosity of the liquid has an inverse relationship with K. Higher viscosity (such as hydraulic oil in low-temperature environments) results in a smaller K value because viscous friction significantly hinders fluid movement—a critical consideration when operating a hydraulic drive system in extreme conditions.

Additionally, the roughness of the flow channel's inner wall affects the K value. When the Reynolds number is high, rough surfaces exacerbate turbulence, causing the K value to decrease by 5%-15%. This turbulence effect must be carefully managed in high-performance hydraulic drive system applications.

Factors Influencing K Value

Flow Cross-Sectional Area (A)

The flow cross-sectional area A is an intuitive parameter determining flow rate, showing a positive correlation with flow rate. In practical applications, the calculation of A must consider the effective flow cross-section of the flow channel—a key design consideration in any hydraulic drive system.

For valve port structures, A equals the product of valve opening and flow width. For pipeline systems, it is the area of the circular cross-section (A = πd²/4).

Notably, when fluid flows through a suddenly expanding or contracting cross-section, local contraction occurs, and the effective flow area A becomes smaller than the geometrically calculated value. A contraction coefficient (usually 0.6-0.9) must be introduced for correction; otherwise, deviations in flow rate calculation will occur.

Proper calculation of A is essential for accurate flow prediction in a hydraulic drive system, directly impacting system efficiency and performance. Engineers must carefully account for these factors when designing components for a hydraulic drive system.

Flow Area Calculations

A = πd²/4

Circular pipe cross-sectional area

Exponent m: The Critical Parameter

The exponent m is a key indicator distinguishing different flow channel types, and its value directly reflects the nonlinearity between pressure difference and flow rate in a hydraulic drive system. Understanding m is fundamental to designing and analyzing any hydraulic drive system.

Slender Orifice

L/d > 40

m = 1

For slender orifices where the length-diameter ratio exceeds 40, fluid flow is in a laminar state, resulting in a strict linear relationship between flow rate and pressure difference.

This linearity makes slender orifices ideal for flow control components in a hydraulic drive system, as their predictable behavior simplifies system design.

Thin-Walled Orifice

L/d < 0.5

m = 0.5

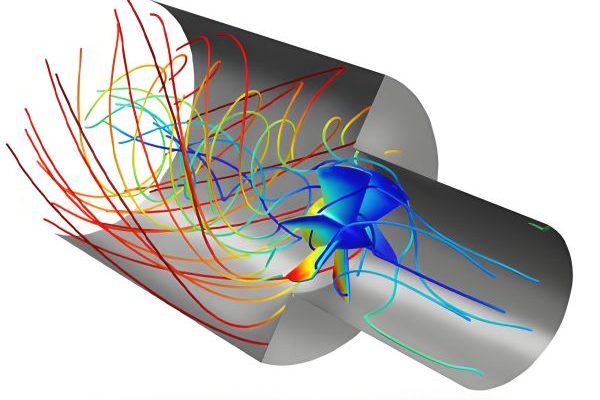

For thin-walled orifices with length-diameter ratio less than 0.5, fluid contracts sharply at the orifice, forming a jet with turbulent flow characteristics.

This creates a nonlinear relationship where flow rate is proportional to the square root of pressure difference, a characteristic widely utilized in measurement devices within a hydraulic drive system.

Short Orifice

1 < L/d < 40

0.5 < m < 1

Most practical flow channels in a hydraulic drive system fall between slender and thin-walled categories, with m values varying based on the specific length-diameter ratio.

These transitional flow characteristics require careful experimental calibration of m values to ensure accurate flow predictions in a hydraulic drive system.

Flow Rate vs Pressure Difference for Different m Values

Transitional Flow Characteristics

In practical hydraulic drive system applications, most flow channels are neither absolutely slender nor ideally thin-walled orifices (such as short orifices with 1 < L/d < 40). In these cases, the m value falls between 0.5 and 1, with specific values depending on the L/d ratio: when L/d = 10, m ≈ 0.7; when L/d = 20, m ≈ 0.85.

m Value vs L/d Ratio

This transitional state exhibits flow characteristics with both linear and nonlinear features. During the design of a hydraulic drive system, experimental calibration of the m value is necessary to improve calculation accuracy.

The precise determination of m becomes particularly critical in high-precision hydraulic drive system applications, where even small errors in flow prediction can lead to significant performance deviations.

Engineers must carefully evaluate the operating conditions of the hydraulic drive system when selecting appropriate m values, considering factors such as fluid viscosity, temperature variations, and potential changes in flow regime during operation.

Nonlinear Relationship in Hydraulic Systems

The nonlinear relationship revealed by Equation 1-10 (when m ≠ 1) represents one of the most significant differences between hydraulic systems and electrical systems. This fundamental distinction must be thoroughly understood when designing and analyzing a hydraulic drive system.

Hydraulic System (qv = KAΔpm)

- Nonlinear relationship when m ≠ 1

- Flow rate proportional to pressure difference raised to power m

- Pressure fluctuations amplified in a hydraulic drive system

- Requires specialized control algorithms for precision

Electrical System (I = U/R)

- Strictly linear relationship

- Current directly proportional to voltage

- Simpler analysis using superposition principles

- More predictable dynamic response

In electrical circuits, Ohm's law shows a linear relationship between current and voltage (I = U/R). This linear characteristic allows circuit analysis and design to utilize simplified methods such as the superposition principle, unlike the more complex behavior observed in a hydraulic drive system.

In a hydraulic drive system, due to the presence of the m value, the nonlinear relationship between flow rate and pressure difference can cause phenomena such as pressure fluctuation amplification and dynamic response lag. For example, when m = 0.5, if the pressure difference increases by 4 times, the flow rate only increases by 2 times.

This nonlinearity can reduce the control accuracy of hydraulic servo systems in a hydraulic drive system, requiring compensation algorithms or structural optimization (such as using proportional valve ports) for improvement. Advanced hydraulic drive system designs often incorporate adaptive control strategies to mitigate these nonlinear effects.

Conclusion

In summary, the relationship between flow rate and pressure difference in a hydraulic drive system is the result of the combined effects of flow channel structure, liquid properties, and flow state. Each parameter in the fundamental equation qv = KAΔpm plays a critical role in determining system behavior.

In engineering applications, it is necessary to determine the m value based on the specific L/d ratio, combined with accurate calculations of K and A, to precisely predict flow characteristics. This knowledge is essential for optimizing the design of hydraulic components and improving system performance in any hydraulic drive system.

As hydraulic technology continues to advance, a deeper understanding of these fundamental relationships will drive innovations in hydraulic drive system design, leading to more efficient, precise, and reliable hydraulic systems for diverse industrial applications.