Introduction to Hydraulic Power Systems

Piston-type hydraulic variable displacement pumps and motors represent the pinnacle of fluid power technology, offering exceptional efficiency, precision, and versatility across numerous industrial applications. These sophisticated devices convert mechanical energy into hydraulic energy and vice versa, forming the backbone of modern hydraulic systems that power automated manufacturing equipment, including precision molding machines for optical transceiver housings and components.

At the heart of many industrial machines, you'll find either a hydraulic pump or a hydraulic motor, with how does a hydraulic motor work being a key aspect, often working in tandem to provide powerful, controlled motion. The variable displacement capability allows these devices to adjust their output according to system demands, significantly improving energy efficiency compared to fixed displacement alternatives.

This technical overview explores the fundamental principles, design variations, and operational characteristics of these critical components, with special attention to the hydraulic engine concept that underpins their functionality.

Key Advantages

- High power density and compact design

- Precise speed and torque control

- Energy efficiency through variable displacement

- Ability to operate across a wide range of pressures

- Durability and long service life in harsh environments

1. Basic Working Principles of Piston-Type Hydraulic Variable Displacement Pumps & Motors

Both piston-type hydraulic pumps and motors operate on the fundamental principle of displacement—using reciprocating pistons to move fluid and create pressure differentials. While a pump converts mechanical energy into hydraulic energy by pressurizing fluid, a motor does the opposite, converting hydraulic energy back into mechanical energy to produce rotational motion.

Pump Operation

A hydraulic pump functions through a carefully orchestrated sequence of events:

- Mechanical input (typically from an engine or electric motor) drives a rotating shaft

- This rotation causes pistons to reciprocate within their cylinders

- As pistons retract, they create a vacuum that draws fluid into the cylinder through an inlet valve

- As pistons extend, they compress the fluid, forcing it out through an outlet valve at high pressure

- The variable displacement feature allows adjustment of the piston stroke length, changing the volume of fluid displaced per rotation

Motor Operation

A hydraulic motor operates on similar mechanical principles but in reverse:

- High-pressure fluid enters the motor through inlet ports

- The fluid pressure acts on the pistons, forcing them to reciprocate

- This reciprocating motion is converted into rotational motion of the output shaft

- Low-pressure fluid exits through the outlet port after acting on the pistons

- Variable displacement motors can adjust their output speed and torque by changing the effective piston displacement

The hydraulic engine concept encompasses both pump and motor technologies, representing the complete energy conversion cycle within hydraulic systems. This cycle enables efficient power transmission over distances with minimal loss, making hydraulic systems indispensable in many industrial applications.

A critical aspect of both pumps and motors is their ability to maintain volumetric efficiency—the ratio of actual fluid displacement to theoretical displacement. High-quality piston designs minimize internal leakage, ensuring that these devices operate at peak efficiency even under varying pressure conditions.

Piston Pump Working Principle

Diagram showing the basic operation of a swashplate-type piston pump with variable displacement capability

Pressure vs. Flow Rate Characteristics

Performance curve demonstrating how a variable displacement pump adjusts flow rate in response to system pressure

2. Piston-Type Hydraulic Variable Displacement Pumps

Piston-type hydraulic variable displacement pumps are sophisticated devices designed to provide precise control over fluid flow rates while maintaining system pressure. Their ability to adjust output according to demand makes them essential components in energy-efficient hydraulic systems across various industries.

These pumps offer significant advantages over fixed displacement models, particularly in applications like hydraulic pump for outboard motors where operating conditions vary widely. By adjusting their displacement, they can maintain optimal system performance while minimizing energy consumption—a key characteristic that distinguishes high-performance hydraulic engine systems from their less efficient counterparts.

Swashplate-Type Pumps

Swashplate-type pumps are the most common design of piston hydraulic pumps, characterized by a rotating cylinder block containing multiple pistons arranged parallel to the drive shaft. The pistons are connected to a斜盘 (swashplate) at an angle, which converts the rotational motion of the cylinder block into axial piston movement.

The displacement of these pumps is varied by adjusting the angle of the swashplate. A larger angle results in a longer piston stroke and greater displacement, while a smaller angle reduces displacement. Some designs can even reverse the swashplate angle to reverse fluid flow direction.

Bent Axis Pumps

Bent axis pumps feature a cylinder block that is mounted at an angle relative to the drive shaft, eliminating the need for a swashplate. The pistons are connected directly to a flange on the drive shaft through ball joints, creating a more compact design with fewer components.

Variable displacement in bent axis pumps is achieved by adjusting the angle between the cylinder block and the drive shaft. This design typically offers higher operating pressures and greater efficiency than swashplate models, making them ideal for high-performance hydraulic engine applications where space is limited.

Variable Displacement Control Methods

The ability to vary displacement is what distinguishes these pumps from fixed displacement models. This adjustment is achieved through various control mechanisms, each offering specific advantages for different applications:

Pressure-Compensated Control

This system automatically adjusts displacement to maintain a constant outlet pressure. When system pressure reaches a preset level, the pump reduces displacement, maintaining pressure while minimizing flow. This is ideal for applications where pressure stability is critical.

Flow-Controlled Systems

These controls maintain a constant flow rate regardless of pressure variations. They are particularly useful in applications requiring precise speed control, such as conveyor systems or machine tool feeds, where consistent flow is essential.

Electro-Hydraulic Controls

Offering the highest precision, these systems use electronic signals to adjust pump displacement. They can be integrated with computer control systems for complex automation applications, providing exceptional flexibility and response times in modern hydraulic engine designs.

Additional Control Methods

- Load-sensing control: Adjusts output to match the actual system demand, significantly improving energy efficiency by reducing unnecessary flow.

- Torque-limiting control: Prevents pump overload by limiting maximum output torque, protecting both the pump and connected components from damage.

- Manual control: Allows operator adjustment of displacement through mechanical levers, useful in applications requiring direct human intervention.

- Proportional control: Provides infinitely variable displacement adjustment proportional to an input signal, offering precise control for complex operations.

Performance Characteristics

The performance of piston-type hydraulic variable displacement pumps is defined by several key parameters that determine their suitability for specific applications:

Pressure Rating

These pumps typically operate at pressures ranging from 200 to 450 bar (2900 to 6500 psi), with some high-performance models capable of reaching 600 bar (8700 psi). The maximum pressure rating is a critical factor in determining the pump's suitability for heavy-duty applications.

Flow Rate

Flow rate capabilities vary widely, from less than 10 L/min to over 500 L/min, depending on pump size and design. Variable displacement allows this flow rate to be adjusted according to system demands, optimizing energy usage.

Speed Range

Operating speeds typically range from 500 to 3000 RPM, with some specialized models designed for higher or lower speeds. The pump's speed characteristics must be matched to the drive system for optimal performance.

Efficiency

Modern piston pumps achieve volumetric efficiencies of 90-98% and overall efficiencies of 80-95% under optimal conditions. This high efficiency is a key advantage in energy-conscious applications, particularly in hydraulic engine systems where energy recovery is important.

Response Time

The time required to change displacement from minimum to maximum (or vice versa) is critical in dynamic applications. Advanced designs can achieve full displacement changes in less than 100 milliseconds, providing exceptional responsiveness.

Design Considerations

Several important design factors influence the selection and performance of piston-type hydraulic variable displacement pumps:

Fluid Compatibility

Pump materials and seals must be compatible with the hydraulic fluid used, which can range from mineral oils to synthetic fluids and biodegradable options. Fluid viscosity and temperature ranges also impact pump selection and performance.

Contamination Control

Piston pumps are sensitive to fluid contamination due to their close tolerances. Effective filtration systems (typically 10-25 micron ratings) are essential to maintain performance and prevent premature wear.

Mounting Configurations

Pumps are available in various mounting configurations, including flange, foot, and SAE mounts, to accommodate different installation requirements. The mounting arrangement affects both performance and serviceability.

Noise Levels

Modern designs incorporate noise-reduction features such as helical gears, optimized porting, and damping materials. Typical noise levels range from 65 to 85 dB(A), with lower noise options available for sensitive environments.

Maintenance Requirements

Considerations include oil change intervals, filter replacement schedules, and accessibility for routine inspections. Some designs feature cartridge-style elements that simplify maintenance and reduce downtime in critical hydraulic engine applications.

3. Classification Methods for Piston-Type Hydraulic Variable Displacement Pumps & Motors

Piston-type hydraulic variable displacement pumps and motors can be classified through several different systems, each focusing on specific design characteristics or operational parameters. This classification helps engineers select the appropriate component for their specific application requirements.

Understanding these classification methods is essential for navigating the diverse range of available products and making informed decisions about system design. Each classification offers insights into how a particular pump or motor will perform in a given hydraulic engine system.

| Classification Basis | Main Categories | Key Characteristics |

|---|---|---|

| Design Configuration |

|

Determined by piston orientation and method of converting rotational to linear motion |

| Displacement Control |

|

Based on the method used to adjust displacement and maintain system parameters |

| Pressure Rating |

|

Classified by maximum operating pressure capability, affecting structural design |

| Rotation Direction |

|

Determines if operation is restricted to one direction or can reverse flow |

| Application Type |

|

Specialized designs optimized for specific operating environments and requirements |

By Design Configuration

Axial Piston - Swashplate Design

Characterized by pistons arranged parallel to the drive shaft, with a swashplate that converts rotational motion into axial piston movement.

Subtypes: Inline (cylinder block rotates with shaft), Bent axis (cylinder block at angle to shaft)

Radial Piston Design

Features pistons arranged radially around a central cam or eccentric shaft. Fluid is drawn in and expelled as the pistons are pushed outward by centrifugal force or cam action.

Subtypes: Fixed cam, Variable eccentricity, Rotating cylinder block

Axial Piston - Bent Axis Design

Combines features of axial and radial designs with pistons arranged at an angle to the drive shaft, connected via ball joints. This configuration allows for higher pressure operation and more compact design.

By Application and Industry

Industrial Pumps & Motors

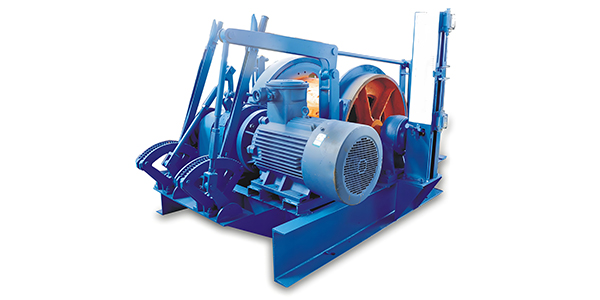

Designed for stationary applications in factories and processing plants. These units prioritize long service life, high efficiency, and precise control. They are commonly used in machine tools, injection molding machines, and material handling systems.

Mobile Hydraulics

Built for use in vehicles and mobile equipment, these units are compact, rugged, and designed to withstand vibration and temperature extremes. Applications include construction machinery, agricultural equipment, and commercial vehicles.

Specialty Applications

Custom designs for specific environments such as marine (corrosion-resistant materials), aerospace (lightweight construction), and energy sector (high-pressure capability). These specialized hydraulic engine components often incorporate unique materials and design features.

4. Applications of Piston-Type Hydraulic Variable Displacement Pumps & Motors

Construction Machinery

Used in excavators, cranes, loaders, and bulldozers for their ability to provide high power density and precise control. The variable displacement feature allows these machines to operate efficiently across a wide range of loads and speeds, making them essential components in modern construction hydraulic engine systems.

Industrial Manufacturing

Critical components in injection molding machines, metal presses, and machine tools where precise speed and pressure control are essential. Their ability to maintain consistent performance under varying loads ensures product quality and process efficiency in manufacturing environments.

Agricultural Machinery

Power farm equipment such as tractors, harvesters, and irrigation systems. The variable displacement capability allows these machines to efficiently perform tasks ranging from light-duty operations to heavy lifting, adapting to changing field conditions.

Marine Applications

Used in ship steering systems, winches, and cargo handling equipment. Marine-grade piston pumps and motors are designed to withstand harsh saltwater environments while providing reliable performance for critical vessel operations.

Aerospace Industry

Power flight control systems, landing gear, and cargo handling in aircraft. These specialized units must meet stringent weight, performance, and reliability requirements, often incorporating advanced materials and designs for optimal operation in the aerospace hydraulic engine environment.

Renewable Energy

Used in wind turbine pitch and yaw controls, solar tracking systems, and hydroelectric power generation. Their precision control and energy efficiency make them ideal for renewable energy applications where operational efficiency directly impacts energy production.

Future Developments in Hydraulic Pump and Motor Technology

The field of hydraulic power continues to evolve, with several key trends shaping the future of piston-type variable displacement pumps and motors:

Increased Energy Efficiency

Ongoing research focuses on reducing internal leakage and friction, with new designs achieving unprecedented efficiency levels. This is particularly important as industries strive to meet stricter environmental regulations and reduce energy consumption in hydraulic engine systems.

Smart Hydraulics

Integration of sensors and electronic controls allows for real-time monitoring and adaptive performance. These "smart" systems can predict maintenance needs, optimize performance based on operating conditions, and communicate with other system components.

Eco-Friendly Solutions

Development of pumps compatible with biodegradable hydraulic fluids and designs that minimize environmental impact. This includes reduced noise emissions and materials that can be recycled at the end of the product lifecycle.

Advanced Materials

New materials such as ceramics, composites, and advanced alloys are being incorporated to improve durability, reduce weight, and enhance performance in extreme operating conditions. These materials enable higher pressure ratings and longer service life.