Valve-Controlled Throttle Speed Control Systems

A comprehensive analysis of hydraulic control systems utilizing fixed-displacement pumps in conjunction with various control valves to regulate speed, with special consideration for hydraulic gear motors integration.

Overview of Hydraulic Throttle Control Systems

These systems represent a fundamental approach to flow control in hydraulic applications, balancing responsiveness with efficiency considerations, often incorporating hydraulic gear motors for specific performance characteristics.

Basic Principles & Operation

System Fundamentals

Valve-controlled throttle speed control systems operate on the principle of regulating fluid flow to hydraulic actuators through the use of control valves. A fixed-displacement pump provides a constant flow rate, while various control valves modulate this flow to achieve the desired speed and force characteristics.

This configuration allows for precise control over actuator movement, making it suitable for applications where accurate speed regulation is required. When paired with hydraulic gear motors, these systems can achieve specific torque characteristics ideal for certain industrial applications.

Speed Regulation Mechanism

The core speed control mechanism involves varying the size of the flow passage through the control valve. By adjusting the valve opening, the flow rate to the actuator is modulated, directly affecting its speed of operation.

This method allows for fine adjustments in speed, even at very low flow rates, which is particularly advantageous in precision applications. Hydraulic gear motors often benefit from this control method due to their inherent responsiveness to flow rate changes.

Key Characteristics

- Rapid response to control inputs, making them suitable for dynamic applications where quick adjustments are necessary

- Capability for minute flow adjustments, enabling precise speed control even at very low operating speeds

- Compatibility with various actuator types, including hydraulic gear motors, cylinders, and other hydraulic motors

- Significant energy losses due to throttling and pressure drops across the control valves

- Lower overall efficiency compared to other control methods, particularly at partial loads

- Predominant use in low-power applications where precision takes precedence over energy efficiency

The integration of hydraulic gear motors within these systems provides unique advantages in certain applications. Hydraulic gear motors offer compact design and high torque output relative to their size, making them ideal companions for throttle control systems in space-constrained environments. The combination of precise flow control from the valve system with the torque characteristics of hydraulic gear motors results in a system that can maintain consistent performance across varying load conditions, despite the inherent efficiency limitations of throttle control.

When properly sized and configured, hydraulic gear motors operating within valve-controlled throttle systems can deliver reliable performance in applications such as conveyor systems, material handling equipment, and small industrial machinery. The key is matching the hydraulic gear motor specifications with the valve characteristics to ensure optimal response and minimize energy losses.

System Configuration & Components

Three-Position, Six-Port Valve in Open-Center System

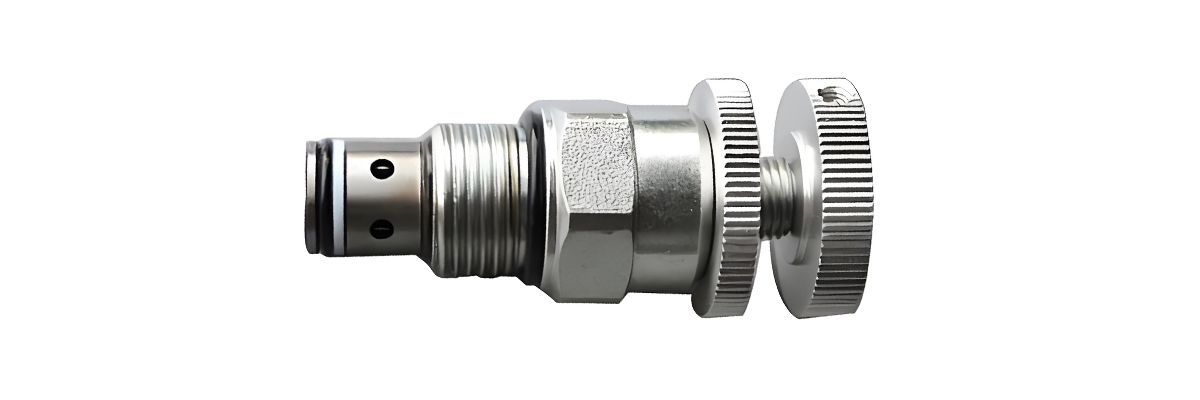

Figure 1-8: Simple Throttle Speed Control with Open-Center System

Schematic representation of a three-position, six-port valve configuration in an open-center hydraulic system, illustrating the dual oil supply paths and integration points for hydraulic gear motors.

The configuration depicted in Figure 1-8 utilizes a three-position, six-port valve in an open-center system for simple throttle speed control. This design incorporates two distinct oil supply paths that work in conjunction to regulate flow to the hydraulic actuators, which may include hydraulic gear motors depending on the specific application requirements.

One of the key advantages of this configuration is its simplicity, which translates to lower initial costs and easier maintenance compared to more complex hydraulic control systems. The open-center design allows for unobstructed flow through the valve when in the neutral position, which can help reduce pressure losses when the system is not actively controlling an actuator. This characteristic can be particularly beneficial when the system includes hydraulic gear motors that may need to free-wheel during certain operational phases.

1 Bypass Oil Path

The first oil supply path is the bypass oil path, which serves as an overflow channel for excess hydraulic fluid. This path is crucial for maintaining system pressure within safe operating limits.

When the control valve is adjusted to restrict flow to the actuator (which could be a hydraulic cylinder or hydraulic gear motors), the excess pressurized oil is diverted through this bypass path. It flows through a pressure relief valve, which maintains system pressure by opening when the pressure exceeds a predetermined setpoint, and then returns to the reservoir tank.

2 Parallel Oil Path

The second oil supply path is the parallel oil path, which delivers hydraulic fluid to the actuators. This path is where the actual speed control occurs through the modulation of the valve opening.

The hydraulic oil flowing into the actuators passes through this parallel path, with the valve orifice size determining the flow rate. By changing the valve opening, the system adjusts the volume of fluid reaching the actuators—whether they are hydraulic cylinders, hydraulic gear motors, or other hydraulic devices—thereby controlling their speed of operation.

Component Interaction

The interaction between these two paths is fundamental to the operation of the system. The fixed-displacement pump continuously delivers a constant volume of fluid per unit time. When the control valve is partially closed, restricting flow to the actuator (such as hydraulic gear motors), only a portion of the pump's output flows through the parallel path to the actuator.

The remaining portion of the pump's output—determined by the valve's position—flows through the bypass path and back to the tank. This division of flow allows for precise control over actuator speed while protecting the system from overpressure conditions.

In systems utilizing hydraulic gear motors, this configuration allows for efficient speed modulation while accommodating the motor's specific flow requirements. The gear motor's displacement characteristics must be carefully matched with the valve's flow capacity to ensure optimal performance and prevent cavitation or excessive pressure drops.

System Components

| Component | Function | Interaction with Hydraulic Gear Motors |

|---|---|---|

| Fixed-Displacement Pump | Provides constant flow rate of hydraulic fluid | Supplies necessary flow to drive hydraulic gear motors at varying speeds |

| Three-Position Six-Port Valve | Controls flow direction and rate to actuators | Modulates flow to hydraulic gear motors for speed control |

| Pressure Relief Valve | Protects system from overpressure | Prevents damage to hydraulic gear motors during pressure spikes |

| Hydraulic Actuators | Convert hydraulic energy to mechanical motion | Hydraulic gear motors serve as rotational actuators in appropriate applications |

| Reservoir | Stores hydraulic fluid and facilitates cooling | Provides clean fluid supply for optimal hydraulic gear motor performance |

Performance Characteristics & Limitations

Speed Regulation Characteristics

The speed regulation characteristics of simple throttle control systems are significantly influenced by two primary factors: load pressure variations and hydraulic pump flow fluctuations. This sensitivity can affect system performance, particularly in applications utilizing hydraulic gear motors where consistent speed under varying loads is important.

When the load on the actuator increases, the pressure drop across the throttle valve decreases, reducing the flow rate and consequently slowing the actuator speed. Conversely, when the load decreases, the pressure drop across the valve increases, leading to a higher flow rate and faster actuator speed. This inherent sensitivity to load changes can result in less consistent performance compared to more complex control systems, especially when operating hydraulic gear motors that may encounter varying torque requirements.

Performance Comparison Chart

Operational Limitations

Poor Handling Performance

Simple throttle control systems exhibit relatively poor handling performance compared to more advanced control architectures. The response characteristics are often sluggish, particularly during transient conditions such as sudden load changes or rapid valve adjustments. This can be problematic in applications requiring precise maneuvering, even when using responsive hydraulic gear motors.

Limited Fine Adjustment Capability

The fine adjustment performance of these systems is also limited. Achieving and maintaining very precise speeds, especially at low operating velocities, can be challenging due to inherent nonlinearities in the flow characteristics through the throttle valve. This limitation can affect applications where precise positioning is required, even with the use of high-precision hydraulic gear motors.

Complex Motion Challenges

One of the most significant drawbacks of this hydraulic circuit design is the interference that occurs between hydraulic actuators when performing compound motions. When multiple actuators (which may include hydraulic gear motors and cylinders) operate simultaneously, they compete for the available hydraulic fluid, creating pressure fluctuations and flow imbalances.

This interaction makes compound motion control quite difficult, as the operation of one actuator affects the performance of others. The协调性 (coordination) of compound actions is notably poor, with actuators experiencing speed variations depending on the load distribution across the system.

For example, when a hydraulic cylinder and hydraulic gear motors operate simultaneously, the cylinder may slow down when the gear motor encounters increased load, even if the operator maintains constant valve positions. This lack of independence between actuators limits the system's versatility in applications requiring complex motion sequences.

Energy Efficiency Considerations

Energy efficiency is a significant concern in valve-controlled throttle systems. The fundamental operating principle involves creating a pressure drop across the control valve to regulate flow, which inherently dissipates energy as heat. This energy loss increases as the valve opening decreases, making these systems particularly inefficient at low speeds and high pressures.

When coupled with hydraulic gear motors, these inefficiencies can be compounded if the motor is not properly matched to the system requirements. Hydraulic gear motors themselves have specific efficiency characteristics that vary with operating pressure and speed, and when operated outside their optimal range within a throttle control system, overall efficiency can suffer further.

Despite these efficiency limitations, the simplicity and cost-effectiveness of throttle control systems make them suitable for low-power applications where the energy losses are manageable and the precision benefits outweigh the operating costs. In such scenarios, hydraulic gear motors can provide an optimal balance between performance and cost, especially when their inherent design advantages align with the application requirements.

Applications & Practical Implementations

Despite their limitations, valve-controlled throttle speed control systems find widespread use in various industrial applications where their specific advantages—such as simplicity, cost-effectiveness, and precise low-speed control—are valued. The integration of hydraulic gear motors expands their application range by providing reliable rotational motion in compact form factors.

Small Industrial Machinery

Widely used in small-scale manufacturing equipment where precise speed control is required but power demands are moderate. Hydraulic gear motors are often employed in these applications due to their compact size and reliable performance.

Material Handling

Used in conveyor systems, small cranes, and lifting equipment where controlled movement of materials is essential. Hydraulic gear motors provide the necessary torque for these applications while maintaining speed control.

Agricultural Equipment

Implemented in various farm machinery for functions like adjustment of implements and controlled movement of components. The durability of hydraulic gear motors makes them suitable for agricultural environments.

System Optimization Strategies

To mitigate some of the limitations of simple throttle control systems, several optimization strategies can be employed. These techniques can enhance performance when using hydraulic gear motors and other actuators:

Pressure Compensation

Incorporating pressure-compensated flow control valves can reduce the system's sensitivity to load changes. These valves maintain a constant pressure drop across the throttle, ensuring more consistent flow rates to hydraulic gear motors regardless of load variations.

Proper Sizing

Ensuring that hydraulic components, including hydraulic gear motors, are properly sized for the application minimizes energy losses and improves efficiency. Matching the motor's displacement and pressure ratings to the system requirements optimizes performance.

System Tuning

Careful adjustment of valve characteristics and pressure settings can significantly improve system response. Tuning the system to match the specific dynamics of hydraulic gear motors can enhance both stability and responsiveness.

Auxiliary Cooling

Implementing adequate cooling systems helps manage the heat generated by energy losses, particularly in applications where hydraulic gear motors operate for extended periods at partial loads.

When specifying hydraulic gear motors for use in throttle control systems, several key parameters must be considered. The motor's displacement, pressure rating, speed range, and torque characteristics must align with the system's flow capabilities and pressure limits. Proper matching ensures that the hydraulic gear motors can operate efficiently within the system's constraints while delivering the required performance.

Maintenance considerations are also important when utilizing hydraulic gear motors in these systems. Regular fluid analysis, filter replacement, and seal inspection help prevent contamination-related damage to both the motors and control valves. Proper maintenance practices can significantly extend the service life of the entire system, including hydraulic gear motors, and maintain consistent performance over time.

Conclusion

Valve-controlled throttle speed control systems represent a fundamental approach to hydraulic control, offering precise speed regulation through the modulation of fluid flow via control valves. These systems, which often incorporate hydraulic gear motors for rotational actuation, provide rapid response and fine adjustment capabilities that make them suitable for various low-power applications.

The basic configuration utilizing a fixed-displacement pump with a three-position, six-port valve in an open-center system creates two critical oil paths: a bypass path for excess fluid and a parallel path for controlled flow to actuators. This design, while simple and cost-effective, exhibits limitations in terms of efficiency, load sensitivity, and coordination of compound motions—factors that must be carefully considered when integrating hydraulic gear motors.

Despite these limitations, when properly designed and applied, these systems deliver reliable performance in applications where their advantages outweigh their drawbacks. The strategic use of hydraulic gear motors enhances their versatility, providing compact, torque-dense actuation in space-constrained environments.

As with any engineering solution, successful implementation requires careful consideration of the specific application requirements, proper component selection—including appropriate hydraulic gear motors—and attention to system optimization. By understanding both the capabilities and limitations of valve-controlled throttle systems, engineers can make informed decisions about their applicability and ensure optimal performance in their intended applications.