Bulk Modulus of Hydraulic Oil

A Comprehensive Guide to Understanding Compressibility and Its Impact on Hydraulic Systems

1.1 Bulk Modulus of Hydraulic Oil

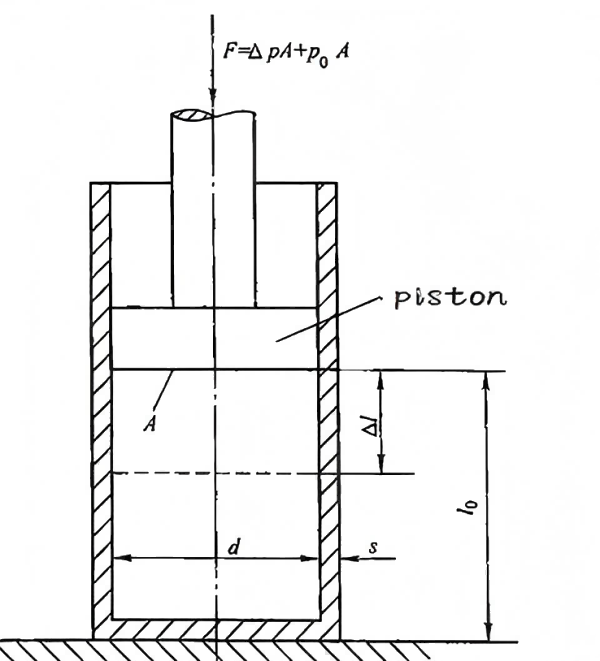

Imagine a hydraulic cylinder filled with oil, its internal structure housing numerous influencing factors. When the piston of the hydraulic cylinder moves, the volume of the liquid inside changes accordingly. As shown in Figure 1-1, a hydraulic cylinder filled with oil has clear structural markings: the piston diameter is d, the cylinder wall thickness is s, and the initial length is l₀. During the piston's movement, it is subjected to a force F = ΔpA + p₀A. Here, by applying pressure to the piston, the original pressure p₀ is increased by Δp. Consequently, the oil, which originally had a volume of V₀ = Al₀, experiences a volume reduction of ΔV₍F₁₎.

Figure 1-1: Hydraulic Cylinder with Piston Movement

Key Parameters

- d Piston Diameter

- s Cylinder Wall Thickness

- l₀ Initial Length

- p₀ Original Pressure

- Δp Pressure Increment

In this process, we can derive the following relationship: ΔV₍F₁₎ = AΔl = - V₀ × (Δp / βₑ) (Equation 1-1). Although this formula may seem complex, each parameter has a clear physical meaning. Here, ΔV₍F₁₎ represents the reduction in the original volume, which is a key manifestation of the change in oil volume due to pressure changes. A is the piston area, which acts as a bridge connecting force and volume change in the entire formula. The force-bearing area of the piston directly affects the transmission effect of pressure in the oil, thereby influencing the change in oil volume. Δl is the piston movement, which直观地 reflects the displacement of the piston under pressure and is closely related to the change in oil volume. βₑ is the bulk modulus of elasticity, which is an important indicator of the oil's resistance to compression.

Understanding Bulk Modulus

The bulk modulus of elasticity βₑ has a special physical meaning. It represents the pressure increment required for a liquid to produce a unit relative volume change. Simply put, the larger βₑ is, the less compressible the oil is, and the stronger its anti-compression ability; conversely, the smaller βₑ is, the more easily the oil is compressed. Under normal circumstances, the bulk modulus βₑ of mineral oil-based hydraulic oil ranges from (1.2 - 2)×10³MPa. From this value, we can see that the compressibility of hydraulic oil is much greater than that of steel, approximately 100 - 150 times that of steel. This characteristic has an important impact in practical applications, especially in occasions with high requirements for hydraulic system performance.

Mathematical Definition

The bulk modulus (βₑ) is mathematically defined as:

βₑ = -V₀ × (Δp/ΔV)

Where:

- V₀ is the original volume

- Δp is the change in pressure

- ΔV is the change in volume

Typical Values

When comparing hydraulic oil vs motor oil, it's essential to note that their bulk modulus values differ significantly. Motor oil, designed primarily for lubrication and heat transfer, typically has a lower bulk modulus than hydraulic oil. This difference arises due to the distinct operational requirements of hydraulic systems, which demand precise control and minimal compressibility to function efficiently.

Why Bulk Modulus Matters

The bulk modulus of hydraulic oil directly influences:

- System response time and precision

- Energy efficiency and power transmission

- Component wear and lifespan

- Overall system stability and performance

Impact of Air Contamination on Bulk Modulus

In practical hydraulic systems, it is often inevitable that air mixes into the oil. The presence of air significantly affects the bulk modulus of hydraulic oil. Once air is mixed into the oil, its anti-compression ability decreases大幅降低. Studies show that when the oil contains 1% entrained air (in the form of bubbles), its elastic modulus drops to 35.6% of that in the pure oil state. This change seriously affects the performance of hydraulic systems, such as slowing down the system response and reducing control accuracy. Therefore, in the design and maintenance of hydraulic systems, we must pay high attention to the problem of air mixing into the oil, especially in situations with high requirements for hydraulic system performance or large system pressures, and minimize the content of entrained air and other volatile substances (such as kerosene, gasoline, etc.) in the oil. Since it is almost impossible to completely eliminate the air in the oil in actual operations, in engineering calculations, the bulk modulus of hydraulic oil is usually taken as about βₑ = 0.7×10³MPa to better conform to the actual situation and ensure that the calculation results can provide a reliable reference for engineering practice.

Effect of Air Content on Bulk Modulus

Comparison: Hydraulic Oil vs Motor Oil

Hydraulic oil and motor oil exhibit different behaviors when contaminated with air due to their distinct formulations and intended applications.

| Property | Hydraulic Oil | Motor Oil |

|---|---|---|

| Bulk Modulus (pure) | (1.2-2)×10³ MPa | (1.0-1.5)×10³ MPa |

| Bulk Modulus (1% air) | ~0.43-0.71×10³ MPa | ~0.35-0.53×10³ MPa |

| Viscosity Index | High (typically 100-150) | Very High (150+) |

| Foam Resistance | Excellent | Good |

| Primary Function | Power transmission | Lubrication & heat transfer |

Key Takeaways: Hydraulic Oil vs Motor Oil

Hydraulic Oil

Optimized for minimal compressibility and efficient power transfer

Motor Oil

Formulated for lubrication and protection under high temperatures

Engineering Considerations for Bulk Modulus

In engineering applications, understanding the bulk modulus of hydraulic oil is critical for designing efficient and reliable hydraulic systems. Here are some key considerations:

System Design

Proper sizing of components and selection of hydraulic oil with appropriate bulk modulus to meet system requirements.

Pressure Requirements

Higher operating pressures demand oils with higher bulk modulus to maintain system stiffness and minimize compressibility effects.

Fluid Maintenance

Regular monitoring and maintenance to control contamination, particularly air and moisture, which degrade bulk modulus.

Calculating System Response

The bulk modulus directly influences the response time and accuracy of hydraulic systems. Consider a system where precision is critical, such as in aerospace or robotics applications. Here, even minor compressibility can lead to significant errors. The following equation helps quantify the effect of bulk modulus on system response:

Where:

Δt

Time delay due to fluid compressibility

V₀

Initial fluid volume

Δp

Pressure change

A

Piston area

βₑ

Bulk modulus of the fluid

v

Piston velocity

Real-World Applications

Understanding the bulk modulus is crucial in various industries:

Industrial Hydraulics

In manufacturing equipment, precise control requires hydraulic oils with high bulk modulus to minimize compressibility effects and ensure accurate movement.

Example: A hydraulic press operating at 3000 psi requires oil with a bulk modulus of at least 1.5×10³ MPa to maintain precision.

Aerospace Systems

Aircraft hydraulic systems demand oils with exceptional bulk modulus to ensure reliable operation under extreme conditions and high pressures.

Example: Landing gear systems use synthetic hydraulic fluids with bulk moduli exceeding 2.0×10³ MPa for maximum safety and performance.

Conclusion

The bulk modulus of hydraulic oil is a critical property that significantly influences the performance and reliability of hydraulic systems. Its value determines the oil's resistance to compression, which in turn affects system response time, precision, and energy efficiency. While mineral oil-based hydraulic oils typically have a bulk modulus ranging from (1.2 - 2)×10³MPa, the presence of contaminants such as air can drastically reduce this value, compromising system performance.

When comparing hydraulic oil vs motor oil, it's evident that their distinct formulations cater to different operational requirements. Hydraulic oil is optimized for minimal compressibility to ensure efficient power transmission, while motor oil focuses on lubrication and heat transfer under high-temperature conditions. Understanding these differences is essential for selecting the appropriate fluid for specific applications.

In engineering practice, maintaining the purity of hydraulic oil and minimizing air contamination are key to preserving its bulk modulus and ensuring optimal system performance. Regular monitoring, proper filtration, and appropriate fluid selection are essential strategies for achieving this goal. By carefully considering the bulk modulus and its influencing factors, engineers can design hydraulic systems that are efficient, reliable, and capable of meeting the demanding requirements of modern industrial and aerospace applications.

References

- 1. Hydraulic Fluid Power - Fundamentals and Applications, 3rd Edition, by John F. Watton

- 2. Fluid Power Technology, 4th Edition, by Anthony Esposito

- 3. "Effect of Air Entrainment on the Bulk Modulus of Hydraulic Fluids" - SAE Technical Paper Series

- 4. ISO 6743-4:2018 - Hydraulic fluids - Classification

- 5. Manufacturer specifications for hydraulic oils and motor oils