In modern industrial applications, efficient flow control is paramount to achieving optimal performance, energy savings, and system longevity. Our comprehensive guide explores the four fundamental flow control systems that form the backbone of hydraulic engineering today. Each system offers unique advantages depending on specific application requirements, operating conditions, and performance goals.

At the heart of all these systems lies the sophisticated interaction between hydraulic pump and motor components, working in harmony to convert mechanical energy into fluid power and back again. Understanding the nuances of each system empowers engineers and decision-makers to select the ideal solution for their specific needs.

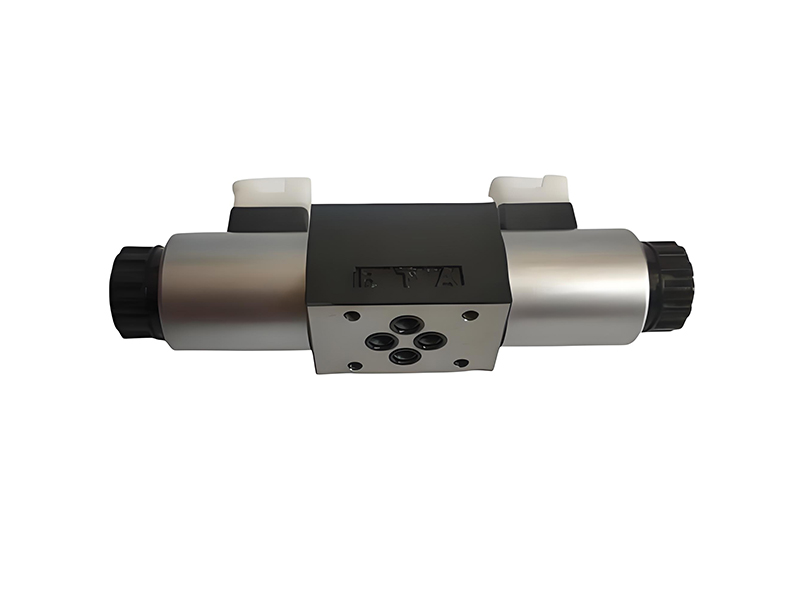

Valve-Controlled (Throttle Speed Control) System

The valve-controlled system, often referred to as throttle speed control, represents one of the most established methods of regulating fluid flow in hydraulic systems. This approach utilizes various valve types to modulate the flow rate to the actuator, thereby controlling speed and motion. The fundamental principle involves restricting flow using a valve, which creates a pressure drop and regulates the amount of fluid reaching the working components.

A key advantage of valve-controlled systems is their simplicity and cost-effectiveness—critical for reliably powering hydraulic gear motors. They typically employ a fixed-displacement pump that maintains constant flow (tailored to the speed requirements of hydraulic gear motors), with excess fluid redirected back to the reservoir through a relief valve when demand is low. This configuration makes them particularly suitable for applications requiring precise speed control and rapid response times.

Central to the operation of these systems is the interaction between the control valves and the hydraulic pump and motor assemblies. The valve acts as the primary flow regulator, while the hydraulic pump and motor provide the necessary pressure and mechanical power conversion. This symbiotic relationship ensures that the system can adapt to varying load conditions while maintaining consistent performance.

Common valve types used in these systems include directional control valves, flow control valves, pressure control valves, and proportional valves. Each valve type offers specific characteristics suited to different applications, from simple on/off control to complex proportional regulation. Modern systems often incorporate electro-hydraulic valves that can be precisely controlled via electronic signals, enabling integration with automation systems and advanced control algorithms.

Despite their advantages, valve-controlled systems do have limitations. The throttling action creates energy losses in the form of heat, which can reduce overall efficiency, particularly in applications with high flow rates or continuous operation. This heat generation often necessitates additional cooling systems, increasing complexity and cost. However, for many applications requiring precise control and moderate duty cycles, these systems remain an excellent choice.

Typical applications for valve-controlled systems include machine tools, injection molding machines, material handling equipment, and various industrial automation processes. Their ability to provide precise control over speed and position makes them indispensable in manufacturing environments where accuracy is paramount.

Valve-Controlled System Architecture

Diagram illustrating the components and flow paths in a typical throttle speed control system, highlighting the integration of control valves with the hydraulic pump and motor.

Key Components:

- Directional control valves for flow path management

- Flow control valves for rate regulation

- Fixed-displacement hydraulic pump

- Hydraulic motor or cylinder actuator

- Pressure relief and safety valves

Performance Characteristics of Valve-Controlled Systems

Pump-Controlled (Volumetric Speed Control) System

The pump-controlled system, also known as volumetric speed control, represents a more energy-efficient alternative to valve-controlled systems by regulating flow at the source rather than restricting it. This approach utilizes variable-displacement pumps—typically hydraulic pump with motor, where the motor provides rotational power to drive pump operation—to adjust the flow rate according to demand, eliminating the energy losses associated with throttling in valve-controlled systems.

In pump-controlled systems, the speed of the actuator is directly proportional to the pump's displacement, making precise control achievable through adjustments to the pump itself. This configuration allows for significant energy savings, as the pump only delivers the exact amount of fluid required by the system at any given moment, rather than maintaining constant flow and diverting excess through relief valves.

The hydraulic pump and motor form the core of these systems, working in tandem to provide efficient power transmission. The variable-displacement pump adjusts its output based on system demands, while the motor converts the hydraulic energy back into mechanical motion. This direct relationship between pump displacement and motor speed enables highly responsive and efficient operation across a wide range of conditions.

Pump-controlled systems offer several advantages over their valve-controlled counterparts, including higher overall efficiency, reduced heat generation, and lower energy consumption. By eliminating the pressure drops associated with flow restriction, these systems can operate at lower temperatures, reducing the need for complex cooling systems and extending component life.

These systems are particularly well-suited for applications requiring large flow rates, continuous operation, or precise speed control under varying load conditions. Common implementations include industrial machinery, mobile equipment, and large-scale manufacturing processes where energy efficiency is a primary concern.

Modern pump-controlled systems often incorporate advanced control algorithms and sensors to continuously monitor and adjust pump displacement in real-time. This allows for adaptive performance that can optimize efficiency while maintaining precise control, even as operating conditions change. The integration of electronic controls with the hydraulic pump and motor technology has further enhanced the capabilities and flexibility of these systems.

While pump-controlled systems typically involve higher initial investment costs compared to valve-controlled systems, the long-term savings in energy consumption and reduced maintenance often justify this expenditure, particularly for high-duty-cycle applications.

Pump-Controlled System Configuration

Schematic representation of a volumetric speed control system, demonstrating how variable displacement pumps modulate flow to control the hydraulic pump and motor operation.

Advantages:

- Higher energy efficiency

- Reduced heat generation

- Lower operating costs

Considerations:

- Higher initial investment

- More complex control

- Specialized maintenance

Efficiency Comparison: Valve vs. Pump Controlled Systems

| Performance Metric | Valve-Controlled System | Pump-Controlled System |

|---|---|---|

| Energy Efficiency | Moderate (50-70%) due to throttling losses | High (80-95%) with minimal energy waste |

| Heat Generation | Significant, often requiring cooling systems | Minimal, reducing cooling requirements |

| Response Time | Very fast due to direct valve actuation | Fast, with advanced controls matching valve performance |

| Hydraulic Pump and Motor Interaction | Pump operates at constant output, motor speed controlled by valves | Pump output varies to directly control motor speed and torque |

| Cost (Initial) | Lower, simpler components | Higher, more complex components |

| Cost (Lifecycle) | Higher due to energy and maintenance costs | Lower with energy savings and reduced wear |

Load-Sensing Control System

Load-sensing control systems represent a sophisticated evolution in hydraulic technology, specifically optimized to match the dynamic load demands of actuators like hydraulic pto drive motor—these motors require variable power input when driving fluctuating external loads (e.g., farm implement operation). By adjusting system pressure and flow based on the hydraulic PTO drive motor’s actual load requirements, the system ensures energy efficiency; it continuously monitors the motor’s pressure demands and adjusts the pump output accordingly, ensuring that only the necessary power is delivered at any given time.

The fundamental principle behind load-sensing systems is maintaining only the minimum pressure required to overcome the current load plus a small margin (typically 10-20 bar). This pressure differential ensures adequate flow control while minimizing energy consumption. When multiple actuators are in use, the system automatically prioritizes the highest pressure requirement, ensuring all functions receive adequate power without unnecessary energy expenditure.

At the heart of these intelligent systems lies a specialized interaction between the hydraulic pump and motor components, working in conjunction with pressure sensors and control valves. The load-sensing pump adjusts its displacement based on feedback from the system, while the motor converts this precisely modulated hydraulic power into mechanical work, resulting in highly efficient operation across varying load conditions.

Load-sensing systems offer several key advantages, including significant energy savings compared to conventional systems, reduced heat generation, and improved controllability. By matching pressure and flow to actual demand, these systems minimize energy waste while maintaining responsive performance. This makes them particularly suitable for multi-actuator systems where different functions may operate simultaneously at varying pressure requirements.

Another notable benefit is the reduction in noise levels, as the hydraulic pump and motor operate at lower pressures when lighter loads are encountered. This not only improves working conditions but also reduces wear on system components, extending overall service life and reducing maintenance requirements.

Modern load-sensing systems often incorporate electronic controls that enhance their capabilities further. These advanced systems can store and recall pressure/flow profiles for specific operations, provide diagnostic information, and integrate with overall machine control systems for coordinated operation. The result is a highly adaptable hydraulic system that can optimize performance for specific tasks while maintaining maximum efficiency.

Applications for load-sensing systems are diverse and include construction equipment, agricultural machinery, material handling systems, and industrial presses. Any application with varying load requirements or multiple actuators can benefit from the efficiency and performance advantages offered by these sophisticated control systems.

Load-Sensing System Operation

Illustration of how load-sensing technology continuously monitors and adjusts pressure and flow to match demand, optimizing the interaction between the hydraulic pump and motor.

System Operation Sequence:

Load pressure is sensed at the actuator and transmitted back to the pump controller

Pump adjusts displacement to maintain optimal pressure differential above load pressure

Flow is modulated to match actuator demand, preventing excess pressure and flow

System continuously adapts to changing load conditions in real-time

Energy Consumption Comparison Across Different Operating Conditions

Variable Speed Control System

Variable speed control systems represent the cutting edge of hydraulic technology, leveraging advances in motor drive technology to achieve unprecedented levels of efficiency and performance—efficiency enabled in part by hydraulic motor speed calculation, which determines the exact rotational speed required to match flow and pressure demands. Unlike traditional systems that rely on fixed-speed electric motors driving variable-displacement pumps, these systems adjust the speed of the electric motor itself to control flow and pressure, with hydraulic motor speed calculation ensuring this adjustment aligns precisely with operational needs, offering a more direct and efficient approach to power management.

The core principle of variable speed systems is simple yet powerful: by adjusting the rotational speed of the electric motor that drives the hydraulic pump, the system can precisely control the flow rate without relying on throttling or complex displacement mechanisms. This direct relationship between motor speed and pump output eliminates many of the energy losses associated with other control methods, resulting in significant efficiency gains.

In these advanced systems, the integration between the electric drive, hydraulic pump and motor components is critical to achieving optimal performance. The variable speed electric motor adjusts its rotational speed based on system demands, directly controlling the hydraulic pump's output. This hydraulic energy is then converted back to mechanical motion by the hydraulic motor, with the entire system working in harmony to deliver precise control with minimal energy loss.

One of the most significant advantages of variable speed control systems is their exceptional energy efficiency across the entire operating range. By matching motor speed to actual demand, these systems avoid the energy losses associated with constant-speed operation and pressure relief valves. This efficiency translates directly to lower operating costs and reduced environmental impact.

Another key benefit is the ability to achieve precise control at very low speeds, which is often challenging for other system types. This makes variable speed systems particularly suitable for applications requiring fine positional control or slow, steady movements. Additionally, the elimination of pressure relief valve operation reduces system noise and heat generation, further enhancing performance and reducing maintenance requirements.

Modern variable speed systems incorporate sophisticated electronic controls and sensors that continuously monitor system parameters and adjust motor speed accordingly. These intelligent control systems can optimize the interaction between the electric drive and hydraulic pump and motor for specific operating conditions, learning and adapting to usage patterns over time.

The integration of variable frequency drives (VFDs) has been instrumental in the development of these systems, allowing for smooth, precise speed control of electric motors. When paired with fixed-displacement hydraulic pumps, these drives create a system that can match the performance of more complex variable-displacement systems at a lower cost while offering superior energy efficiency.

Applications for variable speed control systems continue to expand as the technology matures, including industrial machinery, material handling equipment, renewable energy systems, and precision manufacturing processes. Any application with varying flow requirements or significant periods of partial load operation can benefit dramatically from the efficiency advantages offered by these advanced systems.

Variable Speed System Technology

Configuration of a modern variable speed control system, demonstrating the integration of variable frequency drives with hydraulic pump and motor technology for optimal efficiency.

Key Technological Advancements

-

High-efficiency electric motors

Designed for optimal performance across a wide speed range

-

Advanced variable frequency drives

Precise speed control with energy recovery capabilities

-

Intelligent control algorithms

Adaptive performance optimization based on operating conditions

-

Integrated sensor technology

Real-time monitoring of pressure, flow, and temperature parameters

Efficiency Map: Variable Speed vs. Traditional Systems

Typical Applications and Benefits

Industrial Machinery

Improved cycle times and energy savings in manufacturing processes, with precise control over hydraulic pump and motor operation.

Material Handling

Smooth speed control for lifting and positioning, reducing load sway and improving safety while minimizing energy consumption.

Renewable Energy Systems

Optimized power usage in applications like solar tracking systems, where the hydraulic pump and motor must operate efficiently under varying conditions.

Precision Agriculture

Finely controlled movements for planting and harvesting equipment, improving crop yields while reducing fuel consumption.

System Selection Guide

Valve-Controlled

Best for applications requiring simple control, low initial cost, and rapid response.

Efficiency: Moderate

Cost: Low to moderate

Complexity: Low

Pump-Controlled

Ideal for applications requiring high efficiency with moderate complexity and control range.

Efficiency: High

Cost: Moderate to high

Complexity: Moderate

Load-Sensing

Perfect for multi-actuator systems with varying loads and pressure requirements.

Efficiency: Very high

Cost: Moderate to high

Complexity: Moderate to high

Variable Speed

Superior choice for applications demanding maximum efficiency and precise speed control.

Efficiency: Exceptional

Cost: High initial, low lifecycle

Complexity: High

The selection of the optimal flow control system depends on your specific application requirements, performance goals, and budget considerations. Each system offers unique advantages, with the hydraulic pump and motor technology forming the critical foundation for reliable and efficient operation across all configurations.

Consult Our Hydraulic Systems Experts

Whether you're selecting a new system or optimizing an existing one, our team of specialists can help you choose the perfect solution based on your specific requirements for efficiency, performance, and cost.