Hydraulic Motors: Open and Closed Loop Circuits

A comprehensive guide to understanding the most efficient hydraulic systems and the role of hydraulic pumps and motors in industrial applications.

Understanding Hydraulic Circuits

Hydraulic systems are the workhorses of modern industry, providing power and precision in applications ranging from construction equipment to manufacturing processes. At the heart of these systems lie hydraulic pumps and motors, which convert mechanical energy to fluid energy and back again.

The two primary configurations for hydraulic systems are open loop and closed loop circuits, each with distinct advantages, disadvantages, and ideal applications. Understanding the differences between these systems is crucial for selecting the right technology for your specific needs.

This guide will explore both circuit types in detail, helping you make informed decisions about which system is best suited for your application, while highlighting the critical role of hydraulic pumps and motors in each configuration.

Key Components of Hydraulic Systems

Hydraulic Pumps

The heart of any hydraulic system, pumps convert mechanical energy into fluid pressure. They come in various types including gear, piston, and vane pumps, each suited for different pressure and flow requirements in hydraulic pumps and motors systems.

Hydraulic Motors

These devices convert hydraulic energy back into mechanical energy. Motors are available in similar configurations to pumps and are carefully matched to pump specifications in effective hydraulic pumps and motors setups.

Hydraulic Fluid

Acts as both energy transfer medium and lubricant. The right fluid selection is critical for system efficiency and longevity, particularly in high-performance hydraulic pumps and motors applications.

Control Valves

Regulate fluid flow, pressure, and direction within the system. These components are essential for precise operation and safety in all hydraulic pumps and motors configurations.

Reservoir

Stores hydraulic fluid and helps dissipate heat, remove contaminants, and allow air to escape from the fluid. Particularly important in open loop systems using hydraulic pumps and motors.

Filters & Coolers

Maintain fluid cleanliness and temperature, protecting system components from damage. These are vital for extending the life of hydraulic pumps and motors.

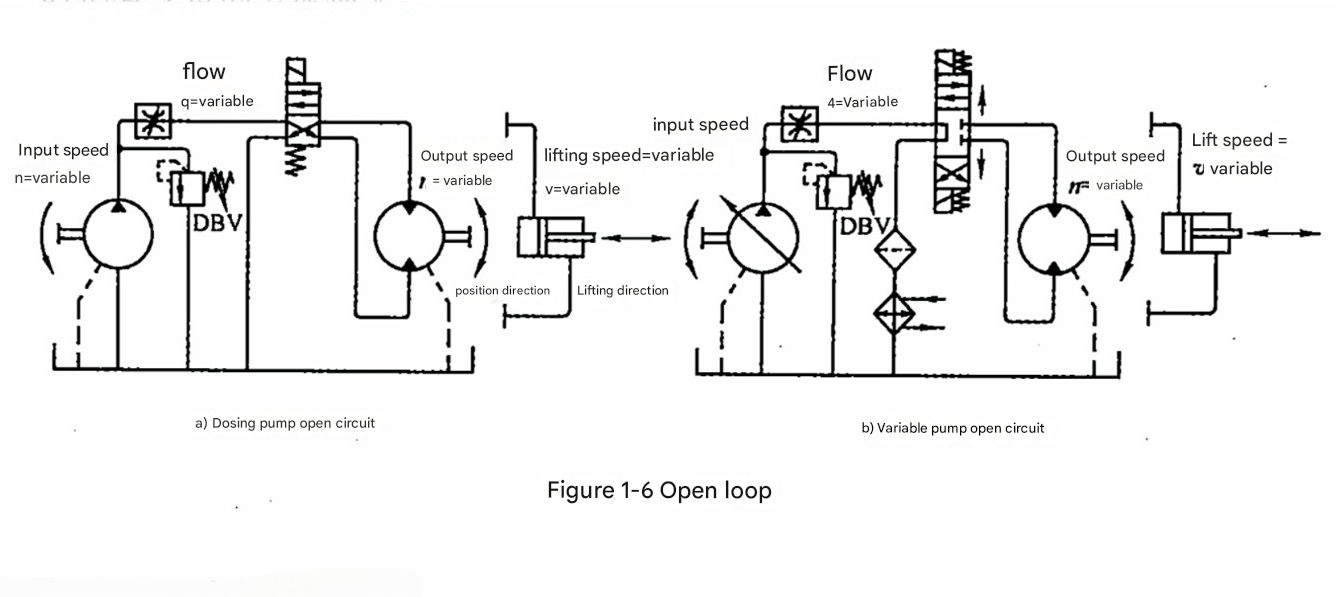

1. Open Loop Circuits

The most common hydraulic system configuration, known for its simplicity and cost-effectiveness in various applications utilizing hydraulic pumps and motors.

How Open Loop Circuits Work

In an open loop circuit, hydraulic fluid follows a one-way path from the reservoir through the system and back to the reservoir. The basic operation sequence is:

- The hydraulic pump draws fluid from the reservoir

- Fluid is pressurized and directed to the hydraulic motor or actuator

- After passing through the motor, fluid flows through a return line

- Returned fluid goes back to the reservoir, completing the cycle

hydraulic pump to motor.This straightforward design makes open loop systems easier to understand, install, and maintain compared to closed loop alternatives. The reservoir serves as both a fluid storage unit and a heat dissipater, which is particularly beneficial for systems using hydraulic pumps and motors in moderate duty cycles.

Key Characteristics of Open Loop Circuits

Reservoir Dependent

Relies on a reservoir to store and cool hydraulic fluid, making system expansion simpler with additional hydraulic pumps and motors.

Directional Control Valves

Uses valves to control fluid direction, allowing reversal of motor rotation without complex components in hydraulic pumps and motors setups.

Simplified Filtration

Easier to implement effective filtration since fluid passes through the reservoir, protecting hydraulic pumps and motors from contaminants.

Pressure Relief Valves

Incorporates relief valves to protect system components during pressure spikes, essential for hydraulic pumps and motors longevity.

Advantages of Open Loop Circuits

Lower Cost

Simpler design with fewer components reduces initial investment and makes hydraulic pumps and motors systems more affordable.

Easier Maintenance

Components are more accessible, and fluid checks/changes are simpler, reducing downtime for hydraulic pumps and motors systems.

Better Cooling

Reservoir provides additional cooling capacity, beneficial for extended operation of hydraulic pumps and motors.

Simpler Fluid Replacement

Easier to drain and replace hydraulic fluid, maintaining optimal performance of hydraulic pumps and motors.

Easier Expansion

Simple to add additional circuits or components to the system, integrating more hydraulic pumps and motors as needed.

Simpler Troubleshooting

Straightforward fluid path makes diagnosing issues with hydraulic pumps and motors easier for maintenance personnel.

Disadvantages of Open Loop Circuits

Fluid Contamination Risk

Reservoir exposes fluid to potential contamination from air, moisture, and particles, which can damage hydraulic pumps and motors over time.

Lower Efficiency

Fluid returning to the reservoir creates pressure losses and inefficiencies, reducing overall performance of hydraulic pumps and motors systems.

Larger Footprint

Reservoir requires additional space, making open loop systems with hydraulic pumps and motors less suitable for compact installations.

Slower Response Times

Longer fluid paths create delays in system response, which can be problematic in applications requiring precision from hydraulic pumps and motors.

Ideal Applications for Open Loop Circuits

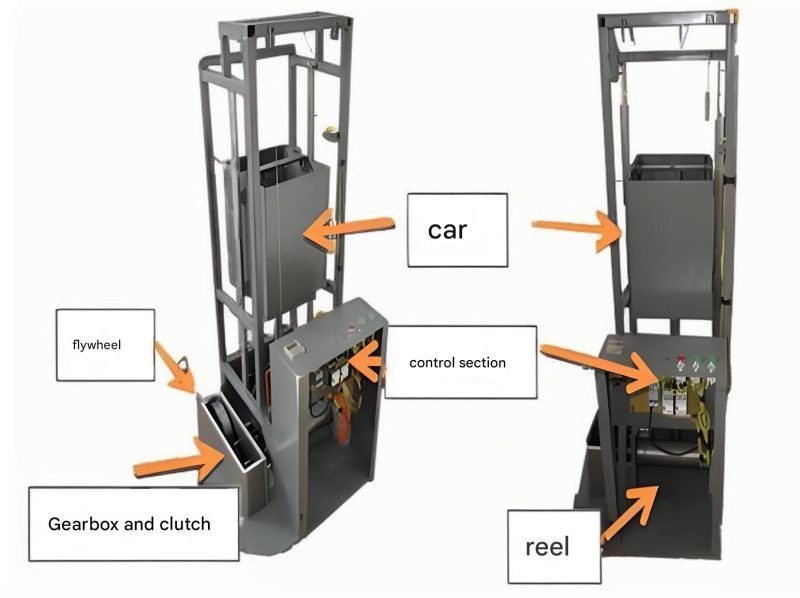

Heavy machinery often utilizes open loop hydraulic systems for their durability and cost-effectiveness

-

Construction Equipment

Excavators, backhoes, and loaders benefit from the rugged simplicity of open loop systems with hydraulic pumps and motors.

-

Agricultural Machinery

Tractors and harvesters use open loop circuits where cost efficiency is prioritized over absolute performance of hydraulic pumps and motors.

-

Material Handling

Forklifts and conveyor systems rely on open loop configurations for their straightforward operation with hydraulic pumps and motors.

-

Mobile Equipment

Trucks and utility vehicles benefit from the reduced space requirements (excluding reservoir) and lower cost of open loop hydraulic pumps and motors systems.

-

Industrial Presses

Many hydraulic presses use open loop systems where cycle times are not critical and cooling is beneficial for hydraulic pumps and motors.

Best Practices for Open Loop Circuit Maintenance

Proper maintenance is crucial for maximizing the lifespan and efficiency of open loop systems utilizing hydraulic pumps and motors. Follow these guidelines:

Regular Fluid Checks

Monitor fluid levels and condition weekly. Change fluid according to manufacturer recommendations to protect hydraulic pumps and motors from premature wear.

Filter Maintenance

Replace filters regularly and monitor for clogging. Contaminant removal is critical for protecting precision components in hydraulic pumps and motors.

Temperature Monitoring

Keep fluid temperatures within recommended ranges. Excessive heat accelerates fluid degradation and reduces performance of hydraulic pumps and motors.

Reservoir Inspection

Check reservoir for water contamination, debris, and proper ventilation. A clean reservoir ensures longer life for hydraulic pumps and motors.

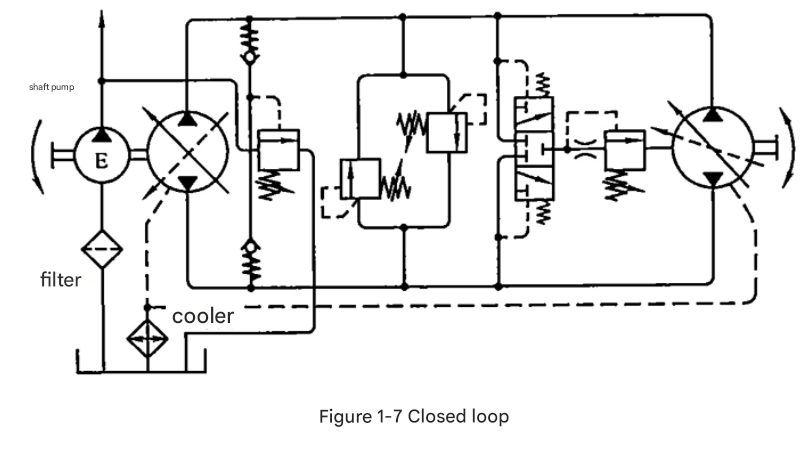

2. Closed Loop Circuits

A more advanced configuration offering superior efficiency and performance for demanding applications using hydraulic pumps and motors.

How Closed Loop Circuits Work

In a closed loop circuit, hydraulic fluid continuously circulates between the hydraulic pump hydraulic motor (i.e., the pump and motor in the circuit) without returning to a reservoir after each cycle. The operation sequence differs significantly from open loop systems:

- Fluid is pumped directly from the hydraulic pump to the hydraulic motor

- After passing through the motor, fluid returns directly to the pump intake

- A small charge pump maintains system pressure and replenishes fluid lost to leakage

- Heat exchangers manage temperature since there's no reservoir for cooling

This design creates a continuous, pressurized loop that eliminates many of the inefficiencies found in open loop systems. The integrated nature of closed loop systems requires more sophisticated hydraulic pumps and motors but delivers superior performance in demanding applications.

Key Characteristics of Closed Loop Circuits

Continuous Fluid Path

Fluid circulates continuously between pump and motor, creating a closed system that enhances efficiency of hydraulic pumps and motors.

Variable Displacement Pumps

Uses sophisticated pumps that can reverse flow direction, eliminating the need for complex valves in hydraulic pumps and motors setups.

Charge Pump System

Incorporates a smaller charge pump to maintain pressure and replenish fluid lost to leakage in hydraulic pumps and motors circuits.

Integrated Cooling

Uses dedicated heat exchangers instead of reservoirs to manage fluid temperature, critical for hydraulic pumps and motors operating under heavy loads.

Advantages of Closed Loop Circuits

Higher Efficiency

Direct fluid path minimizes pressure losses, making closed loop hydraulic pumps and motors systems more energy-efficient.

Faster Response

Shorter fluid paths enable quicker system response, ideal for precision applications with hydraulic pumps and motors.

Compact Design

No large reservoir reduces space requirements, making closed loop hydraulic pumps and motors systems suitable for tight installations.

Reduced Contamination

Sealed system minimizes fluid exposure to contaminants, extending life of hydraulic pumps and motors components.

Precise Control

Superior control over speed and torque, making closed loop hydraulic pumps and motors ideal for precision applications.

Energy Recovery

Can recover and reuse energy during deceleration, improving efficiency of hydraulic pumps and motors systems.

Disadvantages of Closed Loop Circuits

Higher Initial Cost

More complex components and design result in higher upfront investment for closed loop hydraulic pumps and motors systems.

More Complex Maintenance

Specialized knowledge is required for servicing closed loop systems with hydraulic pumps and motors, increasing maintenance costs.

Temperature Management Challenges

Without a reservoir, maintaining proper operating temperatures for hydraulic pumps and motors requires more sophisticated cooling systems.

Limited Expandability

More difficult to add additional circuits or components to closed loop hydraulic pumps and motors systems after initial installation.

Ideal Applications for Closed Loop Circuits

-

Mobile Machinery with Variable Speed

Wheel loaders and mining trucks benefit from the precise speed control of closed loop hydraulic pumps and motors systems.

-

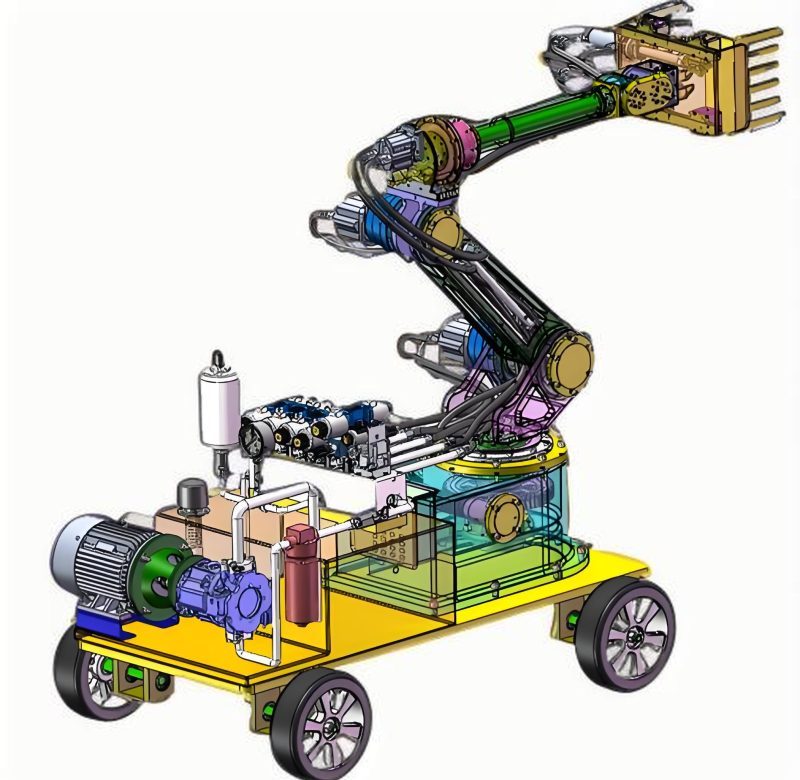

Industrial Robotics

Robotic arms require the precision and responsiveness that closed loop hydraulic pumps and motors configurations provide.

-

Material Processing

Extruders and injection molding machines utilize closed loop systems for their precise pressure control and hydraulic pumps and motors efficiency.

-

Aerospace Applications

Flight control systems and landing gear require the reliability and compact design of closed loop hydraulic pumps and motors.

-

Offshore Equipment

Drilling rigs and marine systems benefit from the contamination resistance of closed loop hydraulic pumps and motors configurations.

Precision equipment like industrial robots relies on closed loop hydraulic systems for accurate control

Best Practices for Closed Loop Circuit Maintenance

Closed loop systems with hydraulic pumps and motors require specialized maintenance to ensure optimal performance and longevity:

Monitor Charge Pressure

Regularly check charge pump pressure to ensure proper system operation and prevent damage to hydraulic pumps and motors.

Cooling System Maintenance

Keep heat exchangers clean and properly functioning to prevent overheating, which is critical for closed loop hydraulic pumps and motors.

Scheduled Fluid Analysis

Regular fluid sampling and analysis helps detect contamination or degradation early, protecting hydraulic pumps and motors from premature failure.

Specialist Servicing

Ensure maintenance is performed by technicians trained in closed loop systems to properly service complex hydraulic pumps and motors components.

Open Loop vs. Closed Loop: A Comparison

Understanding the key differences between these two configurations helps in selecting the right system for your application involving hydraulic pumps and motors.

| Characteristic | Open Loop Circuits | Closed Loop Circuits |

|---|---|---|

| Basic Design | Fluid flows from reservoir through system and back to reservoir | Fluid circulates continuously between pump and motor |

| Reservoir Requirement | Requires large reservoir | No large reservoir needed |

| Efficiency | Lower due to pressure losses and fluid return | Higher due to direct fluid path |

| Response Time | Slower due to longer fluid paths | Faster due to shorter fluid paths |

| Cost | Lower initial cost | Higher initial cost |

| Maintenance | Simpler, easier to perform | More complex, requires specialized knowledge |

| Contamination Risk | Higher due to reservoir exposure | Lower due to closed system |

| Cooling | Natural cooling through reservoir | Requires dedicated heat exchangers |

| Space Requirements | Larger due to reservoir | More compact |

| Control Precision | Good for general applications | Excellent for precision applications |

| Typical Hydraulic Pumps and Motors | Fixed displacement pumps, various motor types | Variable displacement pumps, specialized motors |

Choosing Between Open and Closed Loop Systems

The decision between open and closed loop systems depends on your specific application requirements, budget constraints, and performance needs for hydraulic pumps and motors. Consider the following factors:

When to Choose Open Loop Circuits

- Cost is a primary concern for your hydraulic system

- You need simple maintenance procedures

- Application does not require precise speed control

- Continuous operation with adequate cooling is needed

- Future system expansion is likely

- You have space for a reservoir in your equipment design

When to Choose Closed Loop Circuits

- Precision control is essential for your application

- Energy efficiency is a priority

- Space is limited in your equipment design

- Fast response times are required

- Contamination resistance is critical

- You're willing to invest more upfront for long-term benefits

Final Consideration

Both system types have their place in modern industry. The key is matching the circuit design to your specific application needs while considering the long-term performance and maintenance requirements of hydraulic pumps and motors. Many advanced systems even incorporate hybrid designs, utilizing the strengths of both configurations for optimal performance.

Technical Specifications for Hydraulic Pumps and Motors

Understanding the key specifications helps in selecting the right components for your open or closed loop system.

Hydraulic Pump Specifications

-

Displacement

The volume of fluid pumped per revolution, measured in cc/rev or gpm. Critical for matching hydraulic pumps and motors in a system.

-

Pressure Rating

Maximum operating pressure in psi or bar. Open loop systems typically operate at 2000-3000 psi, while closed loop systems often reach 3000-5000 psi.

-

Flow Rate

Volume of fluid delivered per unit time, measured in gpm or lpm. Determines speed capabilities of hydraulic pumps and motors systems.

-

Efficiency

Volumetric and mechanical efficiency ratings, typically higher in closed loop pump designs used with compatible hydraulic pumps and motors.

-

Rotation Speed

Maximum and operating speed range in rpm, important for matching motor capabilities in hydraulic pumps and motors configurations.

Hydraulic Motor Specifications

-

Displacement

Volume of fluid required to complete one revolution, directly affecting torque output when paired with appropriate hydraulic pumps and motors.

-

Torque Rating

Maximum torque output at specific pressures, measured in ft-lbs or Nm. Critical for matching load requirements in hydraulic pumps and motors systems.

-

Speed Range

Operating speed range in rpm, from minimum to maximum continuous speed capabilities.

-

Pressure Rating

Maximum operating pressure the motor can withstand, must be compatible with system pressure and pump output in hydraulic pumps and motors setups.

-

Mounting Configuration

Flange or foot mounting options, shaft type, and other mechanical interface specifications for proper integration with hydraulic pumps and motors systems.

System Sizing Considerations

Properly sizing your hydraulic system is crucial for optimal performance and longevity of hydraulic pumps and motors. Consider these key factors:

Load Requirements

Calculate the maximum force and torque needed, ensuring hydraulic pumps and motors are rated for 15-20% above expected peak loads.

Cycle Times

Determine required speed and acceleration/deceleration rates to properly size flow capabilities of hydraulic pumps and motors.

Heat Dissipation

Calculate heat generation and ensure adequate cooling capacity, particularly critical for closed loop hydraulic pumps and motors systems.

Duty Cycle

Consider operating vs. idle time ratios when selecting hydraulic pumps and motors for continuous or intermittent service.

Pressure Drops

Account for pressure losses in lines, fittings, and valves when specifying pressure ratings for hydraulic pumps and motors.

Environmental Factors

Temperature extremes, contamination risks, and other environmental factors impact hydraulic pumps and motors selection and system design.

Future Trends in Hydraulic Circuit Design

The hydraulic industry continues to evolve, with new technologies enhancing the performance and efficiency of hydraulic pumps and motors systems.

Innovations Shaping the Industry

Smart Hydraulics

Integration of sensors and IoT technology allows real-time monitoring and optimization of hydraulic pumps and motors performance, enabling predictive maintenance and efficiency improvements.

Energy Recovery Systems

Advanced closed loop systems now incorporate energy recovery technologies that capture and reuse energy during deceleration, significantly improving overall efficiency of hydraulic pumps and motors systems.

Eco-Friendly Fluids

Development of biodegradable hydraulic fluids reduces environmental impact while maintaining performance, creating more sustainable hydraulic pumps and motors systems.

Digital Twin Technology

Virtual replicas of hydraulic systems allow simulation and optimization before physical implementation, reducing development time and improving performance of hydraulic pumps and motors configurations.

The Evolving Role of Hydraulic Pumps and Motors

As industries push for greater efficiency and sustainability, both open and closed loop hydraulic systems are evolving to meet these demands. Open loop systems are becoming more efficient through improved component design, while closed loop systems are becoming more accessible through standardized configurations and smarter controls.Optical Transceiver.

The integration of electronic controls with hydraulic systems is blurring the lines between traditional configurations, creating hybrid systems that leverage the strengths of both open and closed loop designs. These advanced systems maintain the simplicity and cost-effectiveness of open loop architectures where possible, while incorporating closed loop efficiency for critical functions – all while utilizing the latest advancements in hydraulic pumps and motors technology.

Ready to Optimize Your Hydraulic System?

Whether you need an open loop or closed loop configuration, the right hydraulic pumps and motors are crucial for performance and efficiency.Electronic shelf labels.